Key Considerations for Maximizing Manufacturing Efficiency

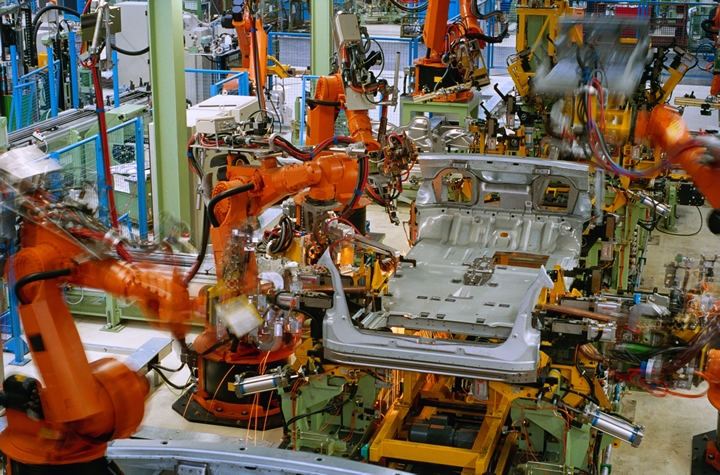

It's true that advanced simulation tools have helped improve the efficiency and effectiveness of robotic workcell design and path planning, but it still remains an incredibly time consuming process.

Game Changer in Logistics

Key work steps are being taken over by intelligent logistics robots, such as automatic storage and retrieval machines and driverless transport systems. To work efficiently and reliably around the clock, these robots need flexible and particularly compact drive solutions.

PACK EXPO 2025 Product Preview

PACK EXPO 2025 takes place September 29th - October 1st in Las Vegas, Nevada. The Exhibit hall floor will be loaded with new products and services. Here is a preview of some things to look forward to at this years event.

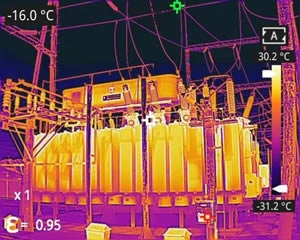

What Makes Thermal Imaging Cameras Useful?

This article will provide you with a comprehensive understanding of what makes thermal imaging cameras useful, including their working principles, system components, and application advantages.

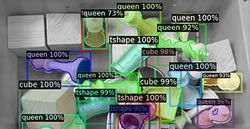

Talking PACK EXPO Las Vegas with CMES Robotics

We will be in the PAC Machinery booth (W-2344). Adding a robot that can perceive virtually any CPG item gives companies the option for a pick-to-bag solution that is going to be truly unique and special on the floor.

The Missing Interface: Designing Trust into a Robotic Future

The next era of robotics and AI won't be defined solely by technical breakthroughs but by how well these systems integrate into human environments. No matter how powerful the sensors or how technical the learning models are, without user trust, adoption will stall.

Talking PACK EXPO Las Vegas with igus

Anyone at the show who visits our booth will be able to find something relevant to their own operations that can solve a key problem and offer improved performance, lower costs, and greater sustainability.

Bumblebee X Powers Taiga Robotics' Mining Automation with AI-Driven Vision

Recently, Taiga Robotics tackled one of mining's most challenging problems, autonomous rod handling, using Teledyne IIS's Bumblebee® X stereo camera. Their solution paired advanced robotic control software with a high-performance stereo vision system.

Let's Talk Technical with onsemi: Robotics and Physical AI

The discussion also emphasizes how AMRs, once limited to controlled indoor settings, are increasingly being adapted for outdoor and unpredictable environments, thanks to advances in sensor integration, edge computing and AI.

What Is The Role of Embedded Cameras in Smart Warehouse Automation?

Cameras ensure that warehouse automation systems use visual data to function with consistency. It helps identify, track, and interact in real time. Discover how warehouse automation cameras work, their use cases, and critical imaging features.

Adaptive Robots

Adaptive robots redefine what's possible in automation by seamlessly blending industrial-grade force control with artificial intelligence. Simple to program, they think, sense, and adapt to effortlessly handle complex environments and diverse tasks with ease.

Order Picking Methods: Finding the Right Strategy for You

Order picking is widely reported to account for 50% to 55% of total warehouse operational costs. Identifying the right picking strategy can have a significant impact on the bottom line.

Why Sensor Resolution Matters More Than You Think in Vibration Control

In high-precision motion control systems like those used in precision manufacturing, the terms "sensor resolution" and "servo bandwidth" are often tossed around interchangeably, sometimes even confused as being functionally synonymous. But they're not.

The Collaborative Revolution: How AI, Digital Twins, and Cobots are Reshaping Manufacturing & Industry

The manufacturing and logistics industries are undergoing a significant transformation due to the integration of AI, digital twins, and collaborative robots. AI acts as the intelligent core, optimizing cobot control, predictive maintenance, and supply chain management.

Real-Time KPI Dashboards: Lessons from the Top 10 Car Makers

Let us once discuss what these industry leaders teach us about tracking lean manufacturing software, why manual KPI tracking methods are losing relevance, and how your factory- from the smallest to a giant-would benefit from the power of digital solutions for manufacturing.

Records 1 to 15 of 2018

Featured Product

High Performance Servo Drives for localized and distributed control applications from Servo2Go.com

Engineered to drive brushless and brush servomotors in torque, velocity or position mode, Servo2Go.com offers a broad selection of servo drives in a wide range of input voltages and output power levels.