The Battery Bottleneck Holding Robotics Back

Robotics is advancing at a remarkable pace. Humanoids are walking out of research labs, delivery bots are rolling onto city streets, and industrial mobile robots are reshaping warehouses. Yet, for all the progress in AI, sensors, and mechanics, one of the biggest constraints isn’t intelligence or dexterity - it’s energy. Today’s batteries force trade-offs in runtime, payload, cost, and design that limit the scale of robotics.

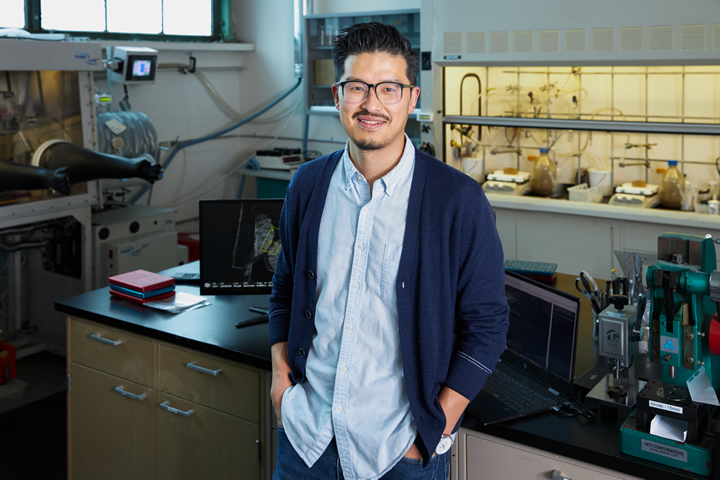

To explore this, Robotics Tomorrow spoke with Jonathan Tan, CEO of Coreshell. Tan has written extensively on energy supply chain vulnerabilities and leads a team developing next-generation silicon-anode batteries. In this conversation, he explains how energy needs vary across robot categories, why current systems are holding back innovation, and what battery breakthroughs could mean for the future of robotics.

Robotics is advancing quickly in areas like AI and mechanics, but you've argued the real bottleneck is power. Why are batteries such a critical factor for the future of robotics?

No matter how intelligent or capable a robot is, it can only operate as long as its power source allows. The most sophisticated humanoid can’t be untethered from a lab if its battery only lasts a couple of hours. Delivery fleets don’t scale if vehicles spend more time charging than working. And industrial robots can’t be deployed in remote or hazardous environments if their runtime is too limited.

What’s striking is that only a few robotics companies are truly treating batteries as core infrastructure. For example, Figure just released their F.03 battery - an integrated design built directly into the robot’s torso with advanced cooling systems. That’s a level of maturity you almost never see. By contrast, many companies are still literally buying off-the-shelf shrink-wrapped batteries from online marketplaces, because their attention is on AI and dexterity demos rather than serial operation. That may get you through a prototype demo or a funding round, but it won’t get you to scaled deployment.

What are the energy and battery needs of robots across categories like humanoids, industrial robots, and delivery bots?

As you know, robots span a wide spectrum of use cases, and their energy demands reflect that. Humanoids need high energy density in compact form factors. They’re trying to pack long runtimes and powerful actuators into tight, humanlike frames. Industrial robots, particularly mobile ones like AMRs or cobots, emphasize reliability and cycle life because they may run around the clock in harsh environments. Delivery bots prioritize lightweight, space-efficient batteries that maximize payload and withstand constant partial charging throughout the day.

Across categories, the common thread is that robotics needs more from batteries than consumer electronics ever did: longer runtime, faster charging, and higher resilience.

What limitations do today's batteries place on robotics innovation?

The biggest bottlenecks are energy density, charge time, form factor, and heat generation. Current lithium-ion systems often limit humanoids to just a few hours of untethered operation. Most take one to two hours to fully recharge, which is unworkable for high-utilization fleets. Battery packs are often bulky, forcing awkward compromises in design and balance. And because robots draw power in bursts (lifting, climbing, accelerating) they generate heat quickly. Thermal issues can force robots to throttle down or fail outright.

Again, this is why Figure’s integrated design matters. They’ve thought about cooling, placement, and density as part of the robot’s architecture. Most companies haven’t matured to that point, and as a result, their robots won’t scale beyond the lab.

What happens if robotics doesn't solve these battery challenges?

Progress could stall. Humanoids may stay tethered to labs rather than scaling into logistics or other use cases. Delivery services could become uneconomical if robots spend too much time charging or replacing batteries. Even industrial robots would face limits in remote or hazardous sites where grid connections aren’t practical. In short, robotics adoption won’t scale if its power source can’t keep up.

How do new approaches like metallurgical silicon anodes change the equation?

Silicon anodes, like what we’re building at Coreshell, offer a meaningful leap over today’s graphite systems. They store more lithium, which translates to higher energy density and longer runtime. In our case, that’s about a 30% bump compared to traditional graphite cells. That extra capacity can go toward lighter batteries, longer missions, or increased payload. Silicon-based chemistries also pair well with fast charging, which makes fleet operations more viable. And as companies like Figure demonstrate, when batteries are treated as core infrastructure, the impact is transformative — our silicon-anode tech is designed to unlock that next leap in runtime and payload.

Finally, why should RoboticsTomorrow readers care about batteries now?

Because energy is the constraint that will determine which robotics companies break out of prototype purgatory and which scale into real businesses. Robotics orders in North America grew 4.3% in the first half of 2025, while revenue rose 7.5%, a trend that underscores the urgency for robust energy infrastructure as automation expands.

Figure’s F.03 battery is a signal to the entire industry: you can’t duct-tape consumer cells together and expect to build a workforce. Batteries aren’t the flashiest part of robotics, but they’re the difference between a humanoid demo and a humanoid workforce.

Featured Product