With the long-stroke gripper ELG from SCHUNK, Girstenbrei Recycling is able to handle construction site fence bases made of recycled material economically, efficiently and ergonomically.

The ELG gets everything out!

The ELG gets everything out!

Case Study from | SCHUNK

.jpg)

Raw materials obtained from old cables: Girstenbrei Recycling breaks down cable, plug and connector scrap and returns the materials into circulation.

In every building, kilometers of cables are laid, hidden or visible, to supply equipment and rooms with electricity and other media. They are multiple lifelines. But what to do with end-of-life or damaged cables? Cables do not belong in the garbage can, they are electrical waste and are collected from dealers or at recycling centers. From there, they are sent to recycling plants, such as Girstenbrei Recycling in Blindheim, Bavaria. "We mainly dismantle cable, plug and connector scrap," explains Managing Director Wolfgang Girstenbrei. The company breaks up the cable composites using multi-stage shredding, and separates the respective components. In addition to aluminum and high-strength alloys, Girstenbrei extracts a lot of residual copper from the metal cores. And the cable sheathing is used to make construction site fence bases in various designs. "Since we started operating the robot system with the ELG gripper from SCHUNK, we've been using the full capacity of our recycling system," says Girstenbrei with conviction.

Automation technology from SCHUNK for optimum use of resources

Everyone knows these traffic sign stands and pedestals – also known as beacon bases – because they are a familiar sight at temporary construction sites. The dark gray, inconspicuous components usually go unnoticed. However, their production process is worth noting. Girstenbrei shreds the cable sheathing – the most common insulation and sheathing materials consist of low smoke zero halogen (LSZH), polyvinyl chloride (PVC), polyurethane (PUR) or polyethylene (PE) – and feeds it into an injection molding machine. Here, the post-consumer plastic is molded into sign bases in 16 different component designs – without employing new plastic and, in turn, completely recyclable. Depending on the variant, the bases weigh between 25 and 35 kilograms. "Nowadays, employees can't lift this weight," reports Wolfgang Girstenbrei. "Manual unloading of the injection molding machine restricted us to around 70 percent of our system's capacity, which was far too slow. The injection molding machine releases a finished component approximately every 20 to 30 seconds. "They've got to be picked up and transported to the pallet area, for the length of a full shift. In our view, manual handling is no longer reasonable," says the Managing Director. Efficiency, ergonomics, employee relief and labor shortages were the reasons for automating this process station.

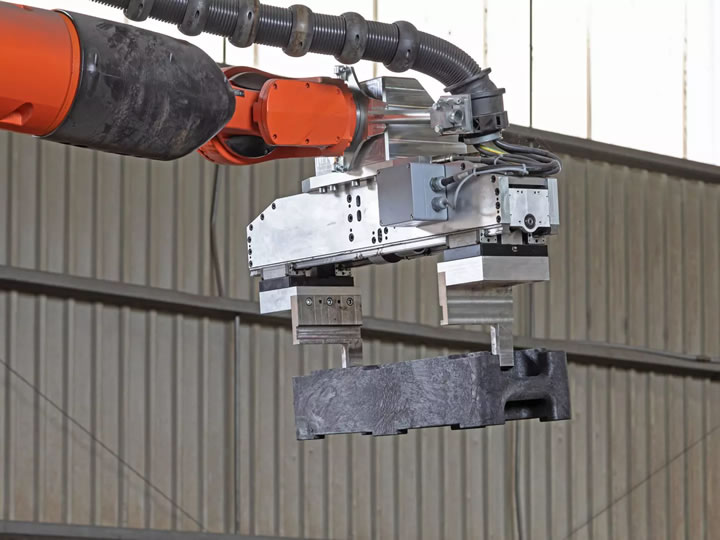

ELG with picked-up construction site fence base: The electric gripper enables flexible adjustment and pre-positioning of the gripper fingers for different components.

Robotic solution with long-stroke gripper ELG

"There was enough space, and we have relevant experience in the field of robot-based automation," assures Hayati Güngör, Project Manager at GD Engineering and Automation in Friedberg, Bavaria. The system integrator specializes in individual, user-specific automation solutions and has designed, programmed and completed a customized system for the fully automatic handling of recycled construction fence bases at Girstenbrei: the components from the injection molding machine are transported to the gripper station via a conveyor system. Here, a KUKA six-axis robot picks up the parts with the ELG electric long-stroke gripper from SCHUNK. A camera application with image recognition directly above the gripping station provides information on which component is involved. "We face the particular challenge of handling 16 different component variants – plus an empty pallet," explains Hayati Güngör. "It's all done by one and the same gripper. There is no retooling, no need to take breaks, no loss of time. All 17 gripping patterns are stored, and thanks to the software we are also flexible for the future."

The ELG thus picks up one ready-molded construction site fence base after the other, and the KUKA robot moves along a linear rail as the seventh axis between the gripper station and the respective pallet positions. The system automatically reports a full pallet; the worker uses a pallet truck to pick it up for putting on the straps and final removal. "This automated system has been running in three-shift operation since January 2024, and it does what it's supposed to: it runs at full capacity," praises Wolfgang Girstenbrei. "It's a successful result and has really reduced the physical strain."

Wolfgang Girstenbrei, Managing Director at Girstenbrei-Recycling (left), Hayati Güngör, project manager at GD Engineering and Automation (center), and Daniel Blessing, technical consultant for gripping and automation technology at SCHUNK (right)

On-the-spot gripper configuration: transparency and time savings

He was also impressed by the high speed of implementation – it only took around six months from the idea to the working system. "This is thanks to the ELG configurator from SCHUNK," says Hayati Güngör. "We'd requested a gripper from SCHUNK for the planned robot system," he continues, summarizing the decision-making process. "SCHUNK presented the ELG and the pneumatic PLG variant, including the configurators, to us in detail during a roadshow. It was immediately clear that we would choose the ELG," says the project manager: "Firstly, the electric gripper is lighter, which makes the handling process more efficient. And secondly, the gripper fingers can be pre-positioned via the motor – an unbeatable advantage for flexibility with so many component variants." The configuration was carried out on the spot and surprised the customer. "The exemplary run-through of the actual handling process on site based on the specific parameters meant that we obtained a quick quotation and immediate costing certainty," reports Hayati Güngör enthusiastically. "This digital process gave us transparency for the specific application and saved us an enormous amount of time when ordering. It was a top consultation between equal partners, and the integration of the gripper was very easy," summarizes Hayati Güngör.

For Girstenbrei Recycling, the ELG configurator was the basis for the rapid success of the project, and the ELG itself is a guarantee for the smooth handling of the construction site fence bases in day-to-day operations: it handles the many component variants reliably and robustly, even in the dusty, harsh environment of a recycling yard. The automation solution avoids time losses and optimizes system output. Last but not least, it relieves the strain on employees and helps to create an ergonomic working environment. With the gripping solution, SCHUNK is making a significant contribution to utilizing the cycle time advantage and addressing skilled labor shortages.

Girstenbrei Recycling relies on state-of-the-art technology. The robot moves on a linear axis between the gripper cell and pallet stations. Photoeectric barriers and motion sensors safeguard the line.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Featured Product

.jpg)